- Stripping Layers: Fiber optic cables have multiple layers, including an outer jacket, buffer coatings (often 900 micron or 250 micron), and the 125 micron glass fiber core.

- Purpose: Strippers are designed to remove these layers precisely without damaging the delicate glass fiber, which is crucial for maintaining signal quality.

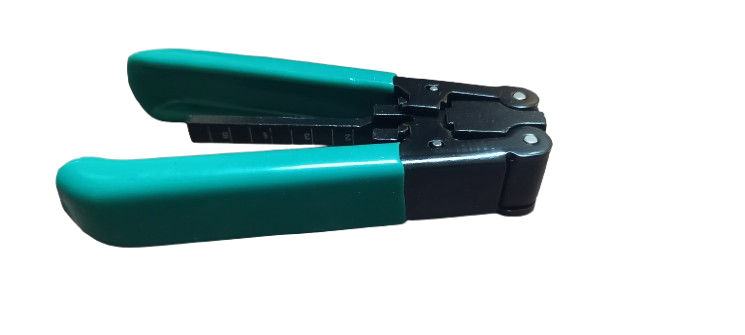

- Common Types:

- Tri-Hole Strippers: These are the most common type, featuring three holes for stripping different layers: outer jacket, 900 micron buffer, and 250 micron coating.

- Other Types: Some strippers are designed for specific cable types or have specialized features like integrated Kevlar cutters.

- Precision and Accuracy: Fiber strippers are designed with precision in mind, with hardened stripping jaws and tight tolerances to ensure clean, accurate stripping.

- Ergonomics: Many strippers have ergonomic handles for comfortable and precise use.

- Outer Jacket Removal: The first hole is used to remove the outer jacket, exposing the buffer coating.

- Buffer Coating Removal: The second hole is used to strip the buffer coating, exposing the 250 micron coating or the bare fiber depending on the cable type.

- Final Stripping: The third hole is used to remove the 250 micron coating, exposing the 125 micron glass fiber.

- Safety Features: Some strippers have safety locks for storage and angled jaw guides to prevent accidental fiber cutting.

- Hole Sizes: Ensure the stripper has the appropriate hole sizes for the types of fiber optic cables you’ll be working with.

- Ergonomics: Look for a comfortable and easy-to-use handle.

- Durability: Choose a stripper made from high-quality materials for long-lasting performance.

- Precision: Select a stripper with hardened stripping jaws and tight tolerances for clean, accurate stripping.