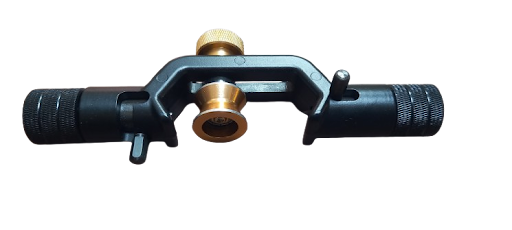

- Precise Stripping:

- Optical fiber sheath strippers are designed to remove the outer protective coating of optical fiber cables without damaging the inner fiber itself.

- They allow for precise stripping of the cable’s jacket, ensuring that the delicate core and cladding are not harmed during the process.

- Adjustable Blade:

- Most optical fiber sheath strippers feature an adjustable blade depth, allowing the user to set the stripping depth based on the diameter and type of fiber optic cable.

- This feature ensures that only the sheath or jacket is removed, while leaving the core and cladding intact.

- Ergonomic Design:

- Many strippers are ergonomically designed with handles that are comfortable to use for extended periods. This reduces hand fatigue and improves user control.

- Some models have non-slip grips for better handling.

- Versatility:

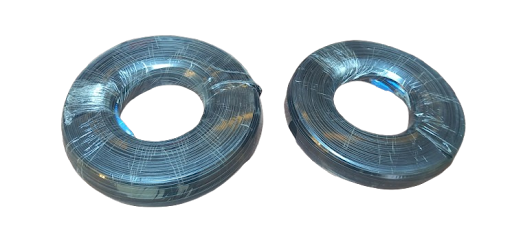

- Optical fiber sheath strippers can be used on a variety of fiber optic cables, including single-mode, multi-mode, and armored cables.

- Some models come with different blade configurations or interchangeable heads to strip various cable types (e.g., buffer-coated or tight-buffered cables).

- Blade Quality and Durability:

- The blades are typically made from high-quality, hardened steel or stainless steel, ensuring durability and longevity.

- The sharp blades allow for clean, smooth cuts, preventing fraying or damage to the fiber.

- Multiple Stripping Functions:

- In addition to stripping the outer jacket, some optical fiber sheath strippers are designed to also strip buffer coatings or other layers that protect the fiber.

- This multi-functionality makes them suitable for use in a variety of fiber preparation tasks.

- Safety Features:

- Many optical fiber sheath strippers come with safety locks to prevent accidental cuts when the tool is not in use.

- The design also minimizes the risk of accidental injury during operation.

- Compact and Portable:

- Most sheath strippers are compact and lightweight, making them easy to carry and handle in tight spaces or during fieldwork.

- Their portability makes them ideal for technicians working in various environments, such as telecom installations or network repairs.

- Ergonomically Designed Handles:

- The handles are often made with soft, ergonomic grips to reduce strain and increase comfort for users who perform repetitive stripping tasks.

- They may also have a spring-loaded mechanism for smoother operation.

- Adjustable for Different Cable Sizes:

- Many sheath strippers allow the user to adjust the tool for different cable diameters. This ensures versatility, allowing it to handle various types of fiber cables with ease.

- Precision and Clean Cuts:

- The stripper’s design ensures that each cut is precise, preventing fiber damage, which could lead to signal loss, poor performance, or fiber breakage.

- Clean, smooth cuts are essential in preparing fibers for splicing or termination.

- Built-in Cable Cutter:

- Some optical fiber sheath strippers come with an integrated cable cutter, allowing users to cut fiber cables at the same time as stripping the sheath.

- Preparing for Splicing/Termination: The primary function is to remove the outer sheath, allowing access to the inner fiber optic cable for splicing or connecting to connectors.

- Protecting the Fiber: Sheath strippers are designed to minimize damage to the delicate fiber optic core during the stripping process.

- Efficiency: They facilitate faster and more accurate cable preparation compared to using traditional methods like knives or hand saws.

- Blade Sharpness: Ensure the blades are sharp and in good condition for optimal performance and to minimize the risk of damaging the fiber.

- Cable Type: Always use the appropriate stripper for the specific type of fiber optic cable you are working with.

- Safety: Follow all safety guidelines when using any tool, including sheath strippers.

- Storage: Store sheath strippers properly to protect the blades and ensure their longevity.

- Select the Right Tool: Choose a sheath stripper that is appropriate for the type and size of the optical fiber cable you are working with.

- Prepare the Cable: Ensure the cable is properly secured and free from obstructions.

- Position the Cable: Place the cable in the stripper’s guide grooves or clamp.

- Strip the Sheath: Operate the stripper according to the manufacturer’s instructions, ensuring a clean and controlled cut.

- Inspect the Fiber: After stripping, carefully inspect the fiber optic core for any damage.

- Longitudinal Sheath Strippers: These tools are designed to cut and remove the sheath along the length of the cable, often used for mid-span branching or when a longer section of cable needs to be stripped.

- Ring Strippers: These tools are designed to cut a ring around the cable sheath, allowing for easy removal of the outer layer.

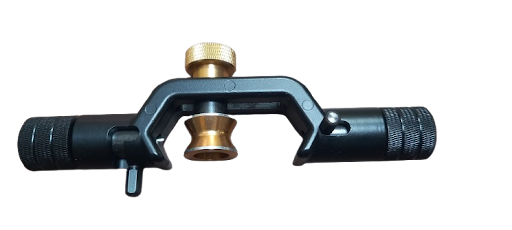

- Adjustable Blade Strippers: Some strippers feature adjustable blades to accommodate different cable sheath thicknesses and diameters.

- Cable Follower/Stabilizer: Some strippers have a drum-type cable follower or other stabilizing features to ensure the cable remains stable during the stripping process.

- FTTH Strippers: Some strippers are specifically designed for FTTH (Fiber to the Home) drop cables, which often have unique sheath designs.

- Universal Strippers: Some strippers are designed to work with various types of fiber optic cables, including tight buffer, loose tube buffer, and breakout cables.