- Most high precision cleavers produce a cleave angle deviation typically <0.5° with very high reliability and low scattering under on-side conditions.

- One-step cleaving operation are a reality now with cleavers. Fiber clamping, bending, scratching and cleaving with one single action.

- Diamond blade presents the highest cleave quality and can last over 10,000 cleaves. They are even adjustable for cleaving fibers with increased tensile strength, e.g. titanium-coated fibers.

- It is easy to cleave an 80um diameter fiber, possible to cleave a 125um diameter fiber, and usually difficult to cleave >200um fibers. To some extent, the difficulty in cleaving these fibers results from the fact that the material of the fiber is not crystalline. Again, torsion will produce a non perpendicular endface. In face, most commercially available angle cleavers rely on torsion. The endface angle is proportional to the amount of torsion.

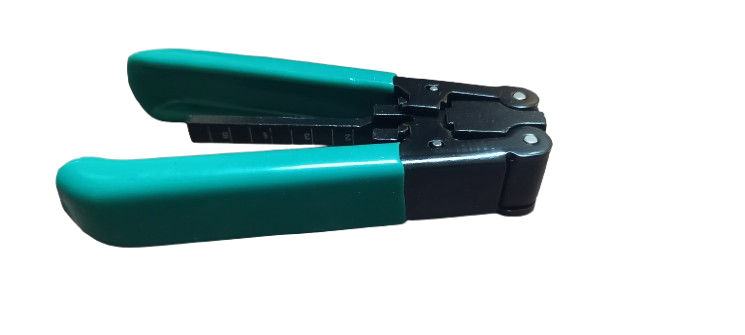

- Function: To produce a precise, clean cut on an optical fiber, crucial for achieving low-loss connections when splicing fibers together.

- Mechanism: The cleaver holds the fiber under tension, scores it with a sharp blade, and then applies controlled force to break the fiber at the scored point, creating a clean break.

- Importance in fiber optics: Essential tool for field technicians working with fiber optic networks, as quality splicing depends on the quality of the fiber end face produced by the cleaver.

- Types of cleavers: Different cleaver designs exist depending on the application, including field cleavers (for basic use) and precision cleavers (for high-precision applications).