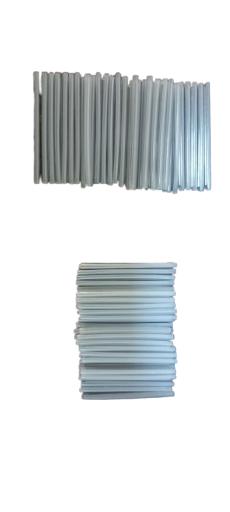

- Splice protection sleeves are essential for providing mechanical protection to the fragile fusion splice, preventing damage from bending, stress, or environmental factors.

- They also help to maintain the integrity of the splice and ensure low optical loss.

- These sleeves are typically made of heat-shrinkable materials like cross-linked polyolefins or other polymers.

- Some sleeves may also incorporate stainless steel needles or other reinforcement elements.

- Various types of splice protection sleeves are available, including micro-fiber sleeves, ribbon fiber sleeves, and FTTH drop cable sleeves.

- They come in different sizes and lengths to accommodate various fiber types and splicing needs.

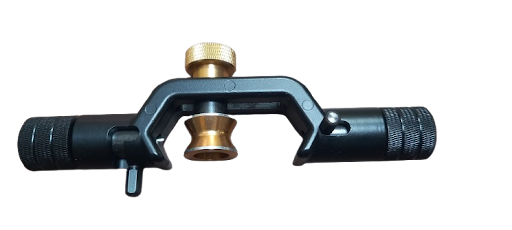

- After the two fiber ends are cleaved and fusion spliced, the splice is placed inside the protection sleeve.

- The sleeve is then heated or otherwise secured to create a permanent and protected splice.

- Durability: Protects the splice from physical damage and environmental conditions.

- Reliability: Ensures a strong and stable connection.

- Low Loss: Helps maintain low optical insertion loss.

- Ease of Installation: Simplifies the splicing process and ensures a quick and easy installation.

- The buffer layer is stripped to expose the fiber.

- The fiber end is cleaved to produce a clean and perpendicular cut.

- The fiber is then fusion spliced to the second fiber end and the splice reinforced with a protection sleeve.